消防の分野において、効率的で信頼性の高い消防車は、公共の安全を確保するために不可欠かつ重要な設備です。ISUZU GIGA 8cbm 水槽付消防車は、消防・救助のために設計された特殊車両として、その優れた性能と完璧な構成により、多くの消防署の第一選択となっています。本マニュアルでは、この消防車の主要構成部品、技術パラメータ、動作原理、操作ガイドライン、メンテナンスポイントについて詳細に解説し、ユーザーが車両の性能をより深く理解し、緊急事態において迅速かつ効果的に任務を遂行できるようにすることを目的としています。

ISUZU GIGA 4x2 8cbm 水槽付消防ポンプ車は、消防活動のために設計された特殊車両です。強力な積載能力と優れた性能を備えたISUZU GIGA大型トラックのシャーシを採用しています。8000Lの大容量水槽を搭載しており、長期的な大規模な消防活動に十分な水源を保証します。水槽は高品質の炭素鋼材で作られており、内部は特別な処理が施されているため、構造の強度を確保し、腐食や汚染を効果的に防止します。

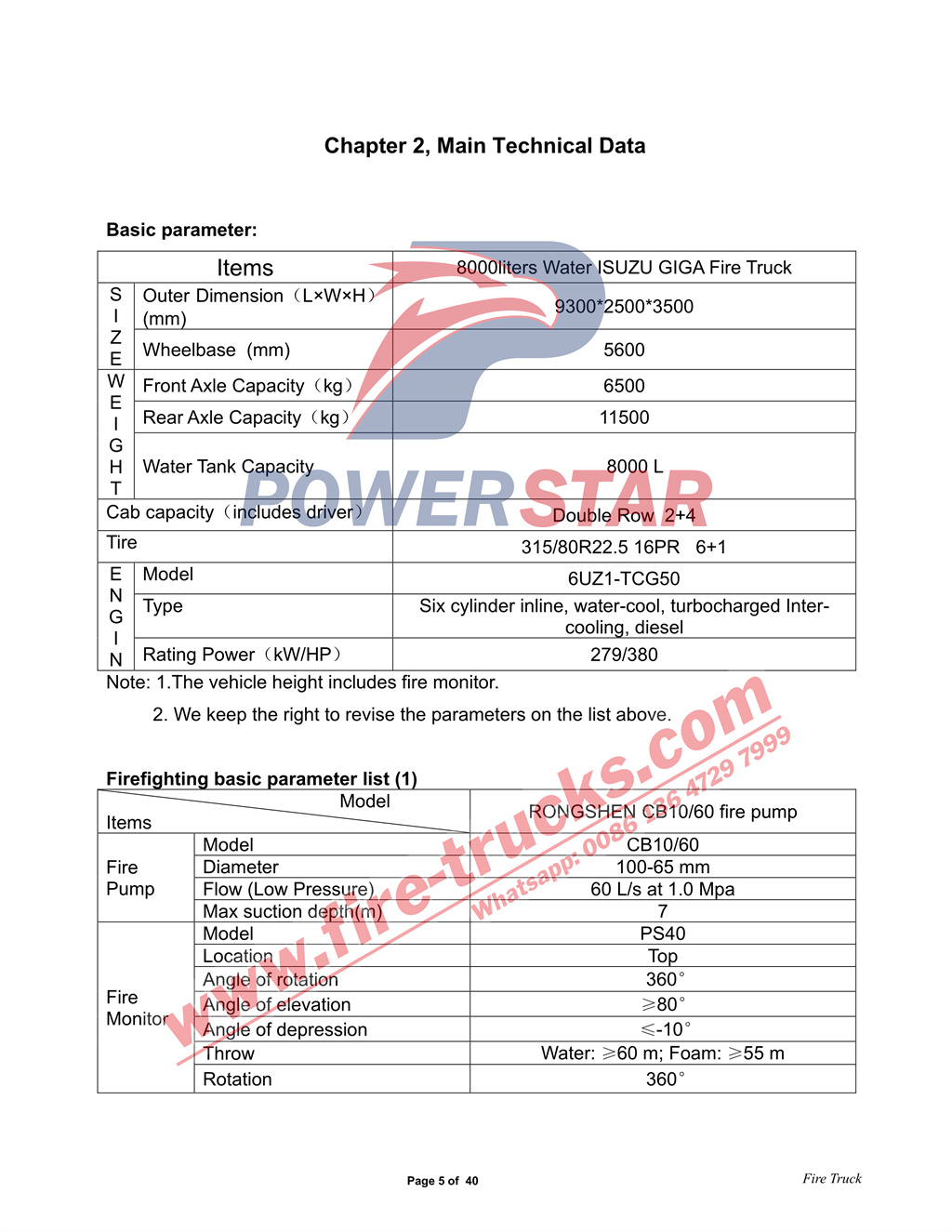

消防ポンプに関しては、CB10/60消防ポンプ(60L/s、1.0MPa)を搭載しており、大流量と高圧力を特徴としています。水槽から水を迅速に汲み上げ、高圧放水銃や消防カノンを通して放水し、火元を効果的に抑制することができます。CB10/60消防ポンプは操作が容易で、性能が安定しています。消防車における主要な設備の一つです。

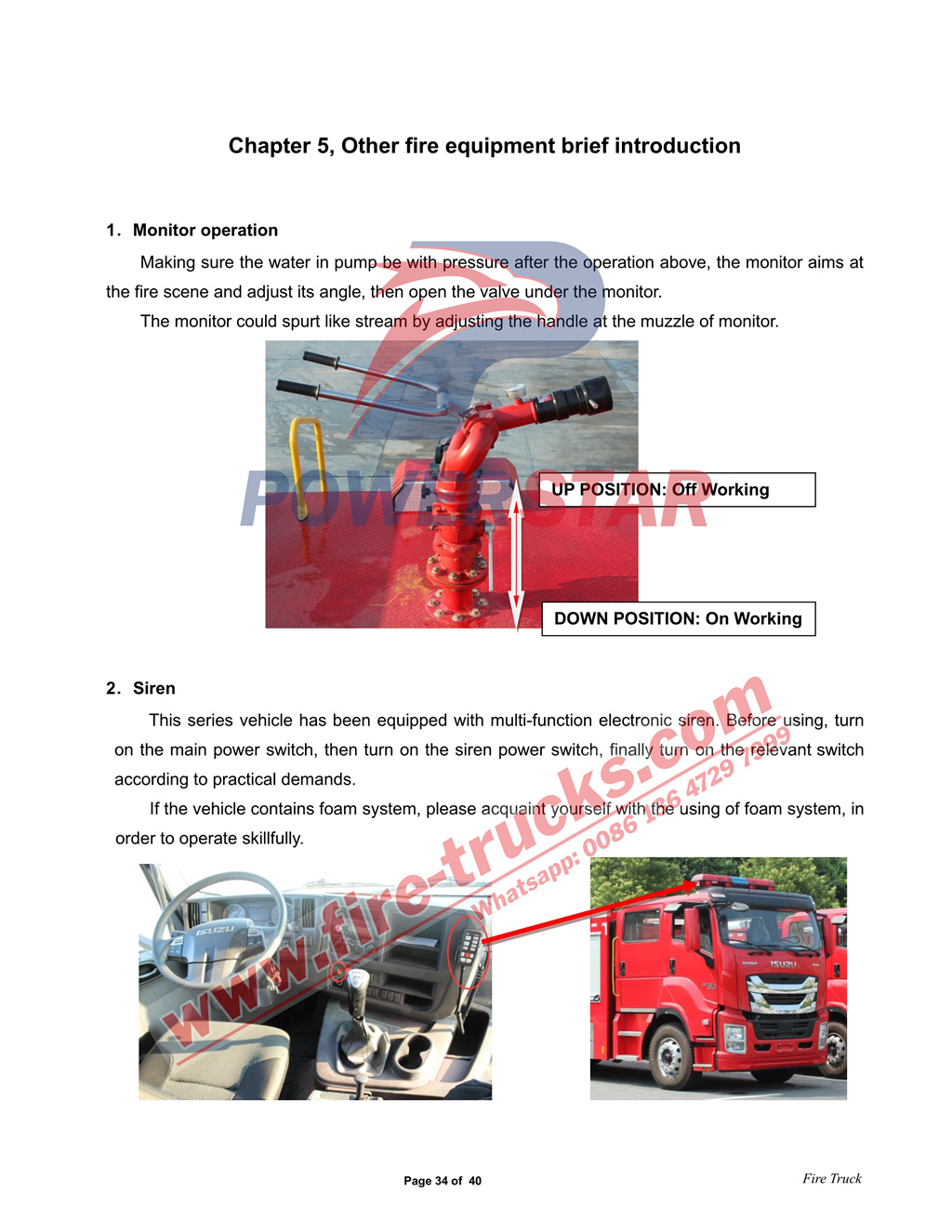

強力な水槽と消防ポンプに加えて、ISUZU GIGA 8cbm 水槽付消防車は、PS40消防モニター(40L/s、0.8MPa、射程≥65メートル、俯仰回転 -30°+70°)も搭載しています。この消防カノンは、射程が長く、カバーエリアが広いという利点があります。様々な火災状況に応じて、噴射角度と流量を柔軟に調整し、的確な消火を行うことができます。同時に、消防カノンの操作も非常に簡単です。消防士は、簡単な操作ハンドルで様々な噴射動作を容易に完了させることができます。

車両のその他の構成においても、ISUZU GIGA 8cbm 泡混合水槽付消防救助車は優れた性能を発揮します。機器箱とポンプ室には、吸水器、送水器、濾水器、ホース、放水銃、斧、シャベル、ツルハシ、レンチ、防火服など、完全な消防機器が装備されており、様々な複雑な火災現場の消防・救助ニーズに対応できます。さらに、車体は高強度素材で作られており、様々な安全保護装置が装備されているため、消防・救助中の安全性を確保します。

ISUZU GIGA 8cbm 水槽付消防車を使用する際には、消防士は車両の様々な性能と操作方法を熟知しておく必要があります。特に、放水、吸水、消防カノンからの放水などの操作を行う際には、操作マニュアルの指示を厳守し、操作の正確性と安全性を確保する必要があります。同時に、車両の定期的な保守点検も不可欠であり、これにより車両の寿命を延ばし、消防の効率を向上させるのに役立ちます。

本文の先頭で全文をダウンロードできます。

次の情報に興味があるかもしれません